Halfway through 2007, the 3rd Gen Ram started being offered with the new-to-the-world 6.7L Cummins powerplant. Emission rules created the need to replace the old 5.9L offering with a “cleaner” option and so the 6.7L was the first Cummins to come with EGR and DPF technology. Here in our Marysville, WA diesel performance shop, we’ve been working on these engines since those first 3rd Gens Rams were sold – So there have been

The 6.7 Cummins was used by Ram all the way into 2018 and has become renowned for its durability and power, despite the emission control systems. But after years of heavy use or high-performance tuning, even this workhorse may start to show signs that its long in the tooth and in need of a rebuild.

If that’s the case with your 6.7L Cummins, it could be the time to look at squeezing some more performance out of it. NWD Performance is the diesel specialist here in the PNW to handle just that project. We know the ins and outs of these engines and can build a performance-oriented 6.7 Cummins rebuild that goes a step further – using upgraded parts and to handle more power than it could in the stock form.

Why Would a 6.7 Cummins Need a Rebuild?

Even a Cummins can wear out or suffer damage over time, especially if it’s been pushed with a bad tune, missed some maintenance intervals or lived it’s life as a fleet or tow rig.

Excessive Blow-By: A telltale sign of worn piston rings or a cracked piston. High boost and high heat can lead to stress cracks and allow gasses to escape through the crankcase. If you are seeing oil residue in the intake or pressure under the oil cap, it is likely time for a rebuild.

Head Gasket Failure: While the 6.7L Cummins handles boost well, extremely high boost can blow the head gasket if stock head bolts stretch. Overheating can also warp the cylinder head, making it impossible for the head gasket to seal properly.

Turbocharger Failure: Oil starvation or overspeed can destroy the turbo, sometimes sending debris into the engine. Bearing wear and overspeeding can cause premature failures, preceded by the telltale whining, grinding and loss of boost pressure.

Fuel System Failures: A bad injector or high-pressure pump can cause internal damage (scored cylinders, fuel contamination).

The 6.7L Cummins Rebuild Process at NW Diesel Performance

At NWD Performance, rebuilding a 6.7 Cummins is a thorough step-by-step process. We know it could be daunting to drop your truck off for open heart surgery. Rest assured that we’ve handled countless 6.7 Cummins rebuilds and are familiar with just about every failure that could happen.

Diagnostics: Comprehensive checks (compression, leak-down, etc.) assess the engine’s condition and confirm the need for a rebuild.

Disassembly: The cab of the truck is pulled up and off the frame, allowing for the engine to be removed (if needed) and completely torn down and making it much easier to inspect all the components.

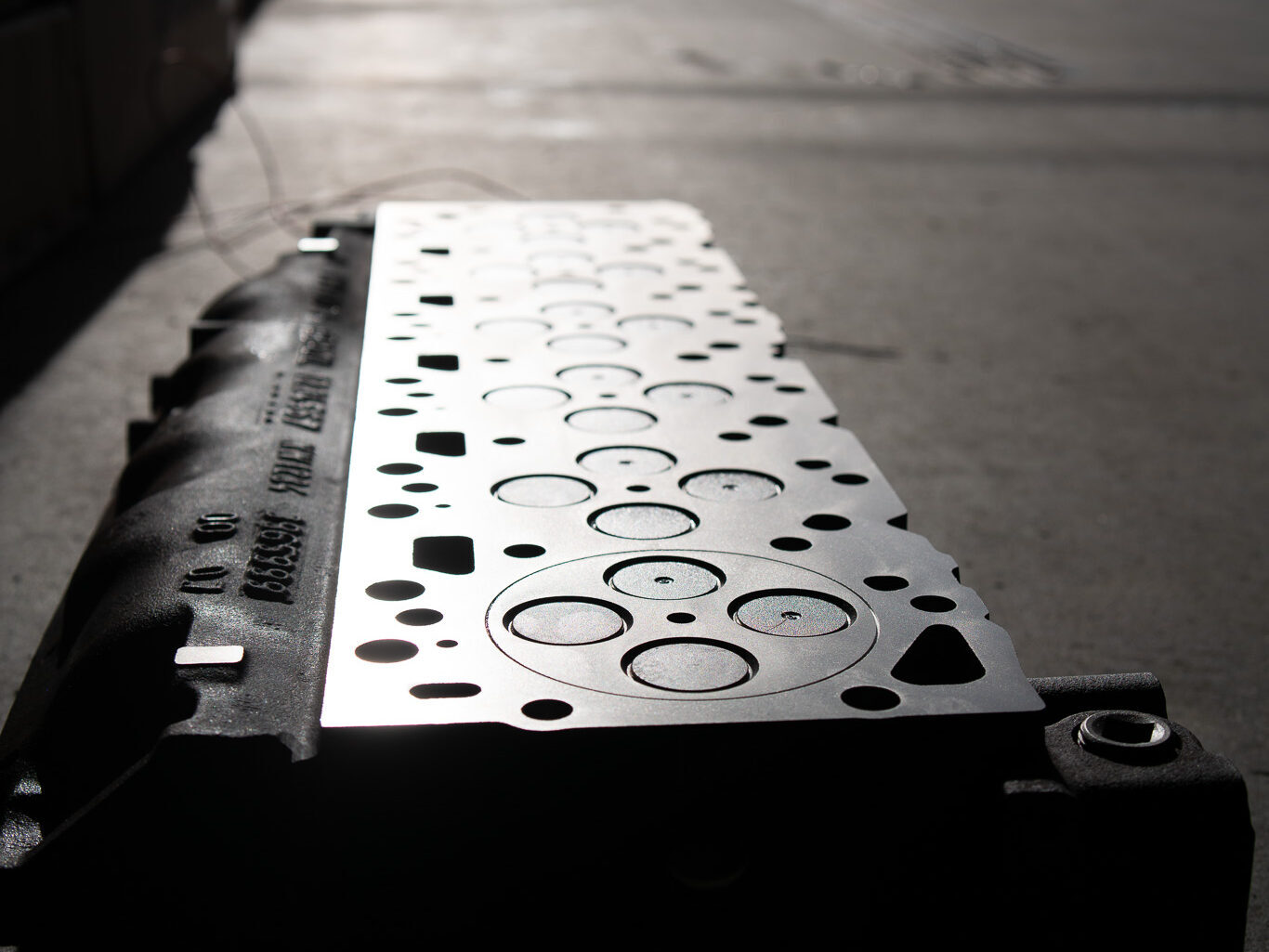

Inspection & Machining: All parts are cleaned and measured. The block and head are checked for cracks or warping, and precision machining (honing cylinders, resurfacing heads, valve work) restores components to spec.

Reassembly: Using new OEM-quality and performance parts, the engine is carefully reassembled. This would be where we can install upgrades like forged pistons and ARP head studs, with all clearances and torque specs set to factory standards.

Tuning & Testing: After assembly, the rebuilt engine is filled with fresh fluids and started for break-in. Finally, the engine is tested to ensure it delivers power smoothly and reliably.

Performance Upgrades to Consider for Your 6.7 Cummins

A rebuild is the perfect time to beef up your 6.7 Cummins with high-performance parts. Depending on your goals and budget, we can help suggest a few go-to options to create more horsepower and increase the durability and longevity of the powerplant.

Heavy-Duty Pistons: Forged pistons (e.g. Mahle) handle higher heat and cylinder pressure to prevent piston failures.

Fresh Cylinder Head: If the stock head has been warped, it could be the perfect time to upgrade to a performance-oriented head. Off-the-shelf options from BD Diesel include CNC-porting for maximum airflow, upgraded valve springs and hardened valve seats – all as a direct bolt-on and ready for more horsepower to be thrown at it.

Head Studs: ARP head stud kits offer far greater clamping force than stock bolts, keeping the head gasket sealed under high boost.

Fuel Injectors: High-flow injectors from brands like Industrial Injection and Dynamite Diesel Products can deliver more fuel for increased power.

Turbocharger Upgrade: Larger turbos or compound setups (e.g. BorgWarner S300/S400 or performance drop-in units from Fleece or BD Diesel) provide extra airflow to support higher horsepower.

Custom Tuning: With all the hardware upgrades, a custom ECU tune (using EFILive, HP Tuners, Smarty, etc.) is crucial to maximize power, efficiency, and reliability.

Proper Tuning & Setup: Beyond assembly, our expert technicians ensure your rebuilt engine is correctly tuned and thoroughly tested. You get an engine that’s not only refreshed but also optimized for power and reliability – a result that will is exactly what will give you a smile when you put your foot down, but also ensure the truck is ready for thousands of miles more.

Rebuilding your 6.7 Cummins for maximum performance can breathe new life into your truck.

By addressing worn components and adding stronger upgrades, you’ll gain like-new dependability along with a big boost in power. Having the engine rebuilt by our team here at NWD Performance in Marysville ensures every step – from diagnosis through to final tuning – is done right. The result is a Cummins engine that’s stronger, more powerful, and ready for anything, giving you lasting performance and peace of mind.